What is OEE?

Overall Equipment Effectiveness (OEE) is a standard metric developed as part of Total Productive Maintenance (TPM) methodology to quantify equipment performance. It combines three essential manufacturing metrics:

Availability

Operating Time vs Planned Time

Performance

Actual Speed vs Planned Speed

Quality

Good Units vs Total Units Produced

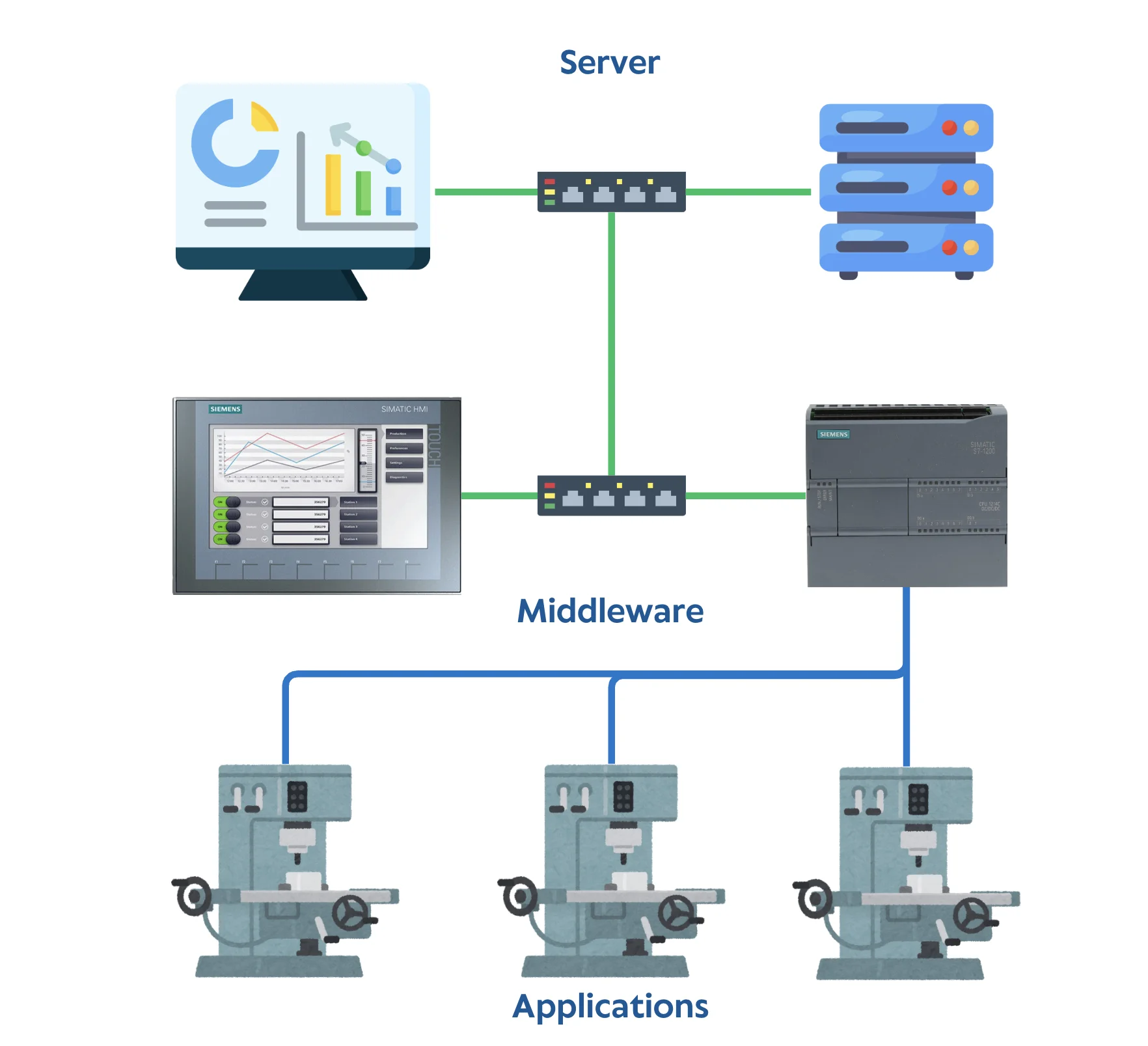

System Topology

Key Points:

- PLC connected to machine sensor to collect produced quantity

- HMI is used by field operator to enter operator ID, downtime and/or reject codes

- Downtime and reject codes is synced with database server

Web Application Features

Dashboard

- Real-time OEE Monitoring – Instantly track Overall Equipment Effectiveness with clear performance metrics

- Breakdown of OEE Components – Availability, Performance, and Quality displayed separately for deeper analysis

- Shift & Line Performance Analysis – Compare OEE by production line and shift to identify trends and inefficiencies

Machine Monitoring

- Production Output vs. Target – Easily compare actual quantity produced against set targets

- Real-time Machine Status – Instantly see which machines are Running, Idle, or Down

- OEE Performance per Machine – Monitor each machine's efficiency

- Downtime Identification – Quickly detect and respond to machine downtimes

Reports

- OEE Performance Trend – Track efficiency and consistency over time

- Downtime Analysis – Breakdown of different downtime causes

- Reject Analysis – Categorized defective products analysis

- Date Range Filter – Analyze production data for specific periods

- Export Report - Custom format exports available

Master Data

- Comprehensive Data Management: Machines, Time Shifts, Downtime Codes, Reject Codes, User Access Control

- Synchronized with HMI systems

- Role-based access control (admin/supervisor)

Ready to Maximize Your Manufacturing Efficiency?

Contact us for a free demo and learn how IonEffex can improve your OEE

Contact Us Now →