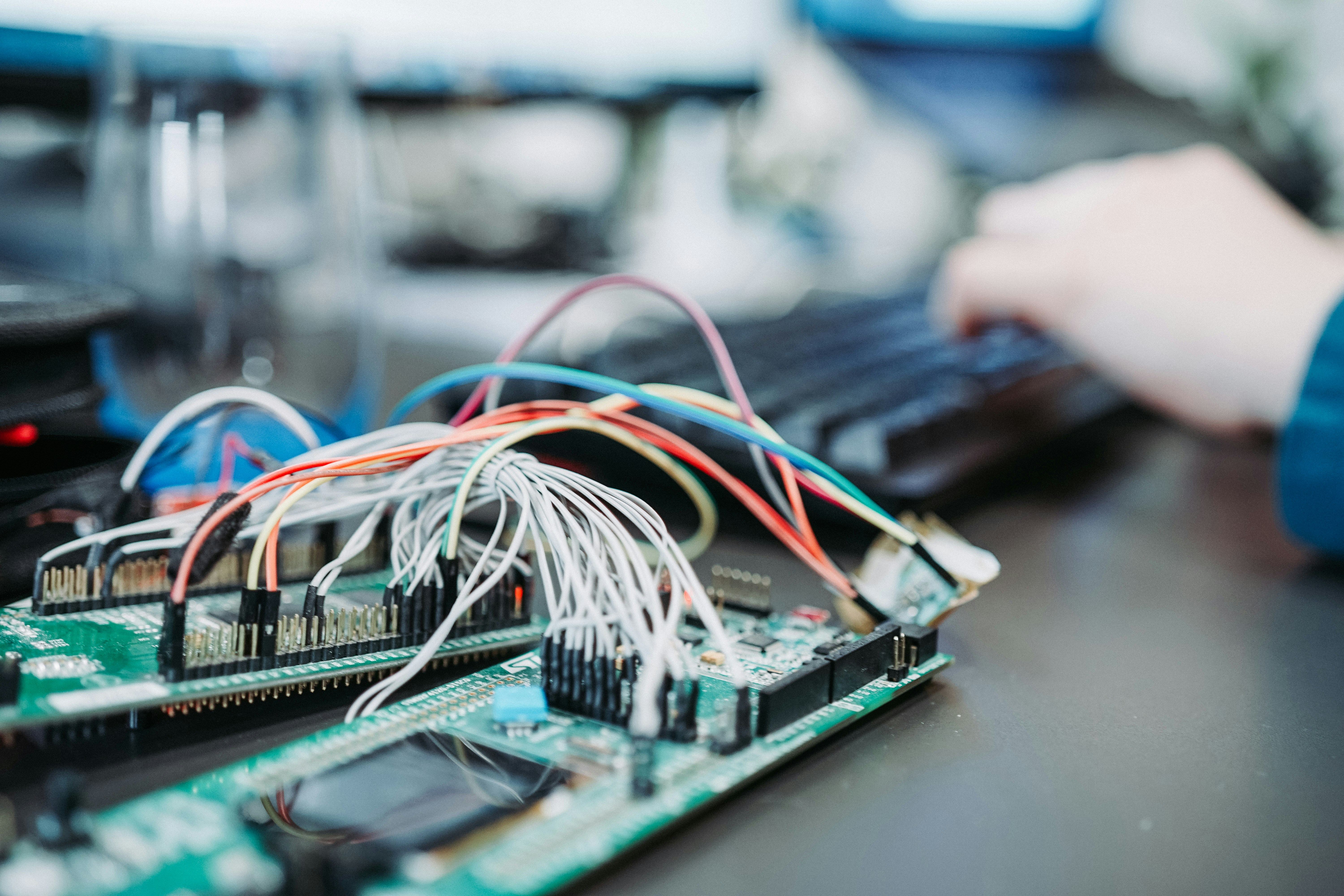

Our Industrial Hardware Services

Our certified engineer team has extensive experience in PLC programming, SCADA development, and industrial system integration for various manufacturing industries across Indonesia

PLC Programming

- ✓Siemens S7 Series (S7-1200, S7-1500, S7-300, S7-400) - Programming with TIA Portal, LAD, FBD, STL, SCL

- ✓Allen-Bradley ControlLogix & CompactLogix - Programming with RSLogix 5000, Studio 5000, ladder logic, structured text

- ✓Mitsubishi FX & Q Series - Programming with GX Works, ladder diagram, instruction list

- ✓Schneider Electric Modicon - Programming with Unity Pro, Concept, SoMachine

- ✓Omron CP & CJ Series - Programming with CX-Programmer, Sysmac Studio, NJ/NX Series for advanced motion control

- ✓ABB AC500 & AC800M Series - Programming with Automation Builder, Control Builder Plus

- ✓Beckhoff TwinCAT - PC-based control, EtherCAT master, real-time programming

- ✓Phoenix Contact ILC & RFC Series - Programming with PC Worx, modular PLC systems

- ✓Wago PFC Series - Programmable field controllers with e!COCKPIT

- ✓B&R Automation - X20, X67 Series with Automation Studio for integrated automation

SCADA Development

- ✓WinCC (Siemens) - HMI/SCADA development, alarm management, historical data logging, recipe management

- ✓FactoryTalk View (Rockwell) - PanelView development, SE/ME applications, alarm and event system

- ✓Wonderware InTouch - SCADA application development, real-time trending, alarm management

- ✓Citect SCADA - Industrial visualization, data acquisition, reporting systems

- ✓Custom web-based SCADA - HTML5/JavaScript SCADA solutions, responsive design, cloud connectivity

- ✓Ignition SCADA (Inductive Automation) - Modern SCADA platform with unlimited tags, web-based HMI

- ✓AVEVA System Platform - Enterprise SCADA with historian, alarm management, trending

- ✓GE iFIX - SCADA development with real-time data acquisition and visualization

- ✓InduSoft Web Studio - HMI/SCADA development with web-based access

Industrial System Integration

- ✓Industrial communication protocols (Modbus RTU/TCP, Profinet, EtherNet/IP, DeviceNet, Profibus, OPC UA, OPC DA, EtherCAT, CANopen, BACnet, MQTT, CoAP)

- ✓Database integration (SQL Server, MySQL, PostgreSQL, Oracle) for historical data and reporting

- ✓MES/ERP system connectivity for production and business data integration

- ✓Cloud platform integration for IoT and cloud-based analytics

- ✓IoT device integration for remote monitoring and control

Industrial Device Integration Solutions

We provide complete integration for various industrial devices commonly used in automation and production control systems

Barcode Integration

Automated data capture and traceability systems for product tracking, inventory management, and quality control

Camera Systems

Vision-based quality inspection, production monitoring, and automated quality control with machine vision

Inverter Control

Precise motor speed and energy management for energy consumption optimization

Flow Meters

Accurate fluid measurement and control for industrial processes, batching, and flow monitoring

Weighing Systems

Precision weight measurement and batching systems for accurate production processes

RFID Integration

Automatic identification and tracking systems with RFID for asset management and supply chain

VFD & Motor Control

Variable Frequency Drive programming and servo drive integration for precise motor control

Industrial Sensors

Industrial sensor integration (pressure, temperature, level, proximity) for monitoring and control

IoT Gateways

Edge computing devices and IoT gateway integration for Industry 4.0 connectivity

Custom Integration

Tailored solutions for unique industrial requirements with custom device integration

Leading Industrial Hardware Services in Indonesia

Ionova is a leading provider of industrial hardware engineering services in Indonesia, specializing in PLC programming and SCADA system development. With our certified and experienced engineer team, we provide comprehensive solutions for your manufacturing industry digital transformation.

Expert PLC Programming - We specialize in programming various leading PLC brands including Siemens S7 Series (S7-1200, S7-1500, S7-300, S7-400) with TIA Portal, Allen-Bradley ControlLogix & CompactLogix with RSLogix 5000 and Studio 5000, Mitsubishi FX & Q Series with GX Works, Schneider Electric Modicon with Unity Pro, Omron CP & CJ Series with CX-Programmer and Sysmac Studio, ABB AC500 & AC800M with Automation Builder, Beckhoff TwinCAT for PC-based control, Phoenix Contact ILC & RFC Series with PC Worx, Wago PFC Series with e!COCKPIT, and B&R Automation X20/X67 Series with Automation Studio. Every project is executed to international standards using official software from each manufacturer.

Professional SCADA Development - Our team has expertise in developing SCADA systems using leading platforms such as WinCC (Siemens) for HMI/SCADA development, FactoryTalk View (Rockwell) for PanelView applications, Wonderware InTouch for real-time trending, Citect SCADA for industrial visualization, Ignition SCADA (Inductive Automation) with unlimited tags and web-based HMI, AVEVA System Platform for enterprise SCADA, GE iFIX for real-time data acquisition, and InduSoft Web Studio for web-based access. We also develop custom web-based SCADA using HTML5 and JavaScript technologies for more flexible and modern solutions.

End-to-End System Integration - We provide complete industrial system integration services, including industrial communication protocol integration such as Modbus RTU/TCP, Profinet, EtherNet/IP, DeviceNet, Profibus, OPC UA, OPC DA, EtherCAT, CANopen, BACnet, MQTT, and CoAP for Industry 4.0 connectivity. We also perform database integration (SQL Server, MySQL, PostgreSQL, Oracle) for historical data, MES/ERP connectivity, cloud platform integration, and IoT device integration along with edge computing devices for remote monitoring and control.

Industrial Device Integration - We have extensive experience in integrating various industrial devices such as barcode and RFID systems for traceability and asset management, camera systems and machine vision for quality inspection, Variable Frequency Drives (VFD) and servo drives for precise motor control, flow meters for fluid measurement, pressure and temperature transmitters for process monitoring, load cells and weighing systems for precise batching, as well as IoT gateways and edge computing devices for Industry 4.0 connectivity.

With a focus on quality, reliability, and efficiency, our industrial hardware engineering services help clients across Indonesia to increase productivity, reduce downtime, and achieve operational excellence in the Industry 4.0 era.